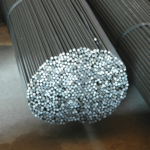

Drawn bars

Drawn bars offered by PRO-MAR S.A. are produced in the parent plant in Poznań, thanks to which the company can process orders at any diameters and cuts of drawn bars in a very wide range of steel grades. Our drawn steel bars are used wherever precision and reliability are of special importance.

PRO-MAR S.A. manufactures drawn bars and wires in many sizes, in various finish conditions, taking into account special technical requirements and characteristics specified by the Customer. We offer round, hexagonal and square bars. We are capable of machining high quality steels in an economical way and according to the level of machinability required by the customer. The production of drawn bars is carried out under the supervision of our best specialists.

All products comply with the requirements of ISO 9000.

We invite you to familiarize yourself in detail with our rich offer.

OUR DRAWN BARS PRODUCTION RANGE

| Dimensions | Dimensional tolerance |

Surface grade (according to PN-EN 10277-1) |

|

| round | 5,0 – 70,0 | h9 , h10, h11 |

1 |

| square | 6,0; 7,0; 8,0 | h9 , h10, h11 |

1 |

-

- Exact dimensions

-

- Bar lengths: from 1 rm to 9 rm

-

- Surface: polished, smooth, hardened after drawing

-

- Bar ends: cut on shears or saw, chamfered on request

-

- Packaging: packages max. 2500 kg, banded with steel tape, marked

-

- Delivery state: +C (or +A+C, +N+C, +FP+C, +AC+C, as requested)

- Protection: bars coated with anti-corrosive oil to provide protection during transport and storage; additionally, bars can be wrapped in foil or covered with anti-corrosive paper

DRAWN ROUNDED BARS according to EN 10278:2003 – h9 / h10 / h11/ h12

- Diameter range: 5 mm – 70 mm

- Exact lengths to be agreed upon

- Delivery state: +N, +A, +FP, +AC

DRAWN ROUNDED BARS according to EN 10278:2003 – h9 / h10 / h11/ h12

- Diameter range: 5 mm – 20 mm

- Delivery state: +N, +A, +FP, +AC

- Maximum coil weight 2000 kg

Our range of drawn and peeled bar grades includes:

- structural and non-alloy steels (S235JR, S355J2, C35, C45, C55, C60, etc.)

- alloy steels (16MnCr5, 20MnCr5, 41Cr4, 42CrMo4, 27MnB5-2, 20MnB4, etc.)

- free-cutting steels (11SMn[Pb]30, etc.)

- spring steels (60S2A, 51CrV4, 54SiCr6, 60SiCr7, etc.)

- OTHER – if you are interested in other grades, please contact us.

At the customer’s request, the surface of the bars can be subjected to defectoscopic inspection by eddy current method according to PN-EN 12084 standard.

Steel drawn in coils:

| Dimensions | Dimensional tolerance | Surface grade (per PN-EN 10277-1) | |

| Ø | 6,0 – 20,0 | h9 , h11 | 1 |

- Exact dimensions

- Surface: smooth, hardened after drawing

- Packaging: banded with steel strap, marked

- Delivery state: +C (or +A+C, +N+C, +FP+C, +AC+C, at request), coils up to 1200 kg

- Protection: steel in coils, coated with anti-corrosion oil to provide protection during transport and storage

An Acceptance Certificate 3.1 in accordance with PN-EN 10204 : 2006 is issued for each product, which is stored by us in electronic form and issued free of charge on request.

Additional services: sawing, tip chamfering, non-destructive testing (ultrasonic/eddy current)

We recommend the offered drawn bars especially for use in the fasteners industry. As a cold forming method, drawing of steel strengthens the strength properties (Rm, Re), which further increases the performance of fasteners such as bolts, anchors, pins, etc.

Thanks to the pre-treated bar surface and precise cross-sectional tolerance, drawn steel bars are used not only in screwmaking plants, but also in the automotive and furniture industries.

One of the most attractive products in our assortment are normalized (+N) or softening -annealed (+A) steels. Heat treatment is carried out in our plant in electric furnaces. Drawn and peeled bars subjected to this treatment are characterized by low hardness and excellent properties facilitating mechanical and plastic processing. In addition, their mechanical properties and structure are the same throughout the bar’s cross-section. Thanks to this, each drawn bar offered by us is a product of the highest quality.

Advantages of heat treatment of drawn bars:

- Increased plasticity of the material

- Homogeneous structure

- Removal of internal stresses

- Reduced machining time

- Lower tool wear

We hold an official license to produce drawn bars intended for the construction and repair of technical equipment subject to official technical supervision.

Offer

- <<Drawn barsDrawing Mill

- <<Peeling Mill

- <<Open-die Forging Mill

- <<Steel Service Centre

- <<STEEL PRODUCTS