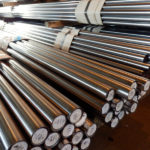

Steel peeling mill

PRO-MAR S.A. has two modern lines for peeling and polishing bars and wires. The production of peeled bars is fully automated – the human role is limited only to supervising the computerised production control system.

Our peelers enable the most versatile and precise peeling of bars and wires on the Polish market. Precise machining on our peelers allows us to achieve h9 tolerances according to EN 10278 for a wide range of materials such as structural steel, high quality steel, including spring steel and tempered steel.

All devices performing bar peeling have a modular design. They are equipped with batch feeders, cutting head, rolling mill-polisher and straightener. Peeled bars may also be tested on a module for testing surface defects or a machine for facing and chamfering of ends, a cutting station, packing station, etc.

The peeling line is equipped with a continuous real-time diameter control system employing laser control instruments for 100% of the machined bars. The peeled bars obtained in this process are characterized by a bright, glossy surface with a very low roughness coefficient [Ra]. Thanks to the removal of decarburized layer from the bars surface, we can deliver our products to even the most demanding customers, including manufacturers of springs for the automotive industry.

The obtained surface quality and dimensional tolerances allow the use of smaller allowances during subsequent processing.

The result of the high processing capacity in the production of peeled bars and the high capacity of our equipment is immediate availability of a wide range of peeled products and reduced lead times for untypical materials, made at the customer’s request.

PRO-MAR S.A. is constantly implementing improvements aimed at increasing the level of automation of production processes in the plant. Our goal is to shorten the time of execution of orders entrusted to us while maintaining the highest level of quality. Thanks to this, every steel bar offered by us is distinguished by the highest quality of workmanship.

We offer bars from our own or entrusted charge.

PEELED BARS

| Dimensions | Dimensional tolerance | Surface grade

((according to PN-EN 10277-1) |

|

| Ø | 10,0 – 98,0 | h9, h10, h11 | 1, 2, 3 |

- Exact dimensions

- Bar lengths: 3 – 12 rm

- Surface: peeled, polished, smooth, glossy, without surface defects

- Bar ends: sawn or chamfered on request

- Packaging: standard – 1500 kg package, banded with steel tape, marked

- Delivery state: +SH (or +N+SH, +QT+SH and others, depending on request)

At the customer’s request, the surface of the bars can be subjected to defectoscopic inspection by eddy current method according to PN-EN 12084 standard.

Steel peeled in coils

| Dimensions | Dimensional tolerance | Surface grade

(according to PN-EN 10277-1) |

|

| Ø | 6,0 – 26,0 | h9, h10, h11 | 1, 2, 3 |

- Exact dimensions

- Surface: peeled, ground

- Pakowanie: kręgi max.2000 kg, spinane stalową taśmą, opisane

- Delivery state: +SL (or + SH, +M+SL, +N+SL and others, on customer’s request)

We hold license to produce peeled bars intended for the construction and repair of technical equipment subject to official technical supervision.

Offer

- <<Drawn barsDrawing Mill

- <<Peeling Mill

- <<Open-die Forging Mill

- <<Steel Service Centre

- <<STEEL PRODUCTS